Amount of Material

It is a common misconception that a layer of clay is all that is necessary to effectively contain a pond’s contents. First, there may be local, State, and federal regulations that must be considered for your project. This is usually dependent on the type of containment. Second, there are various factors that must be taken into consideration when determining the required thickness of clay. The hydraulic conductivity of the clay is one important characteristic. This is then followed by the head of leachate above the clay liner, and finally the flow rate of the leachate. In many cases, multiple layers of clay must be laid and compacted together to achieve the permeability requirements of the project. All these factors can help determine the thickness of clay necessary for a containment project.

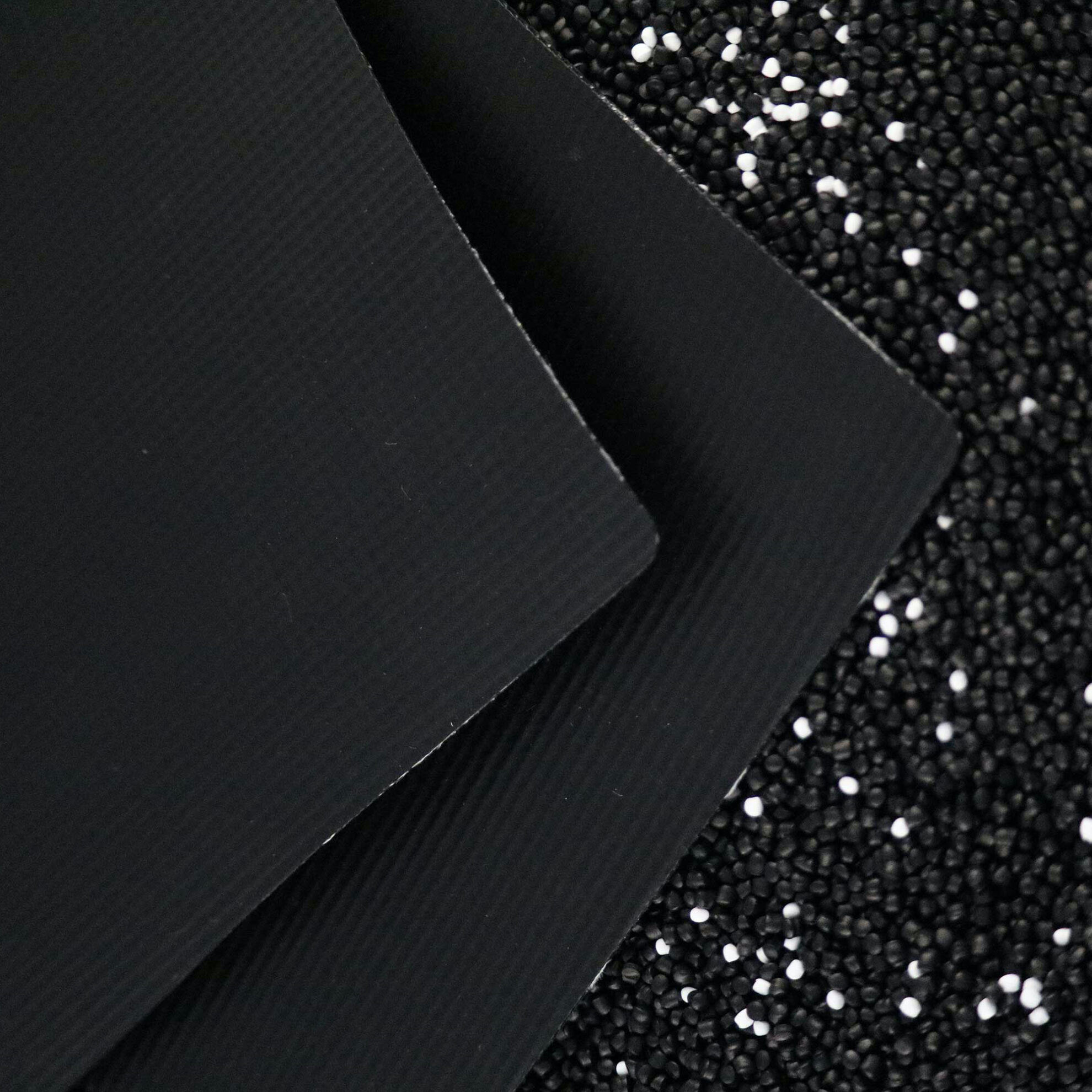

The type and thickness of a geosynthetic lining system specified for a containment project is determined by a variety of factors. Chief among them is whether the lining system will be left exposed to the elements or buried with a layer of fill. Certain geosynthetics such as PVC are not conducive to being exposed to UV radiation. The type(s) of material being contained is also an important element to consider. Geosynthetics must be compatible with the contaminants they are exposed to. In many applications, the correct geosynthetic lining system will do the job of keeping a containment leak-fee for years to come.

Longevity

Mother Nature has many factors that can impact the longevity of a clay liner. Over time, freeze and thaw cycles can cause cracking of clay lining systems. Cracking can be avoided with the addition of cover soil to protect the liner from temperature variation. The addition of cover soil can increase both the cost and installation time of the project. Underlying subgrade soil stability can also cause problems both during and post-installation. This is especially prevalent in areas of the country with karst topography, where ground and stormwater cause shifting soils.

Flora and fauna can also disrupt an otherwise intact clay lining system. Burrowing animals can cause irreparable damage in a short period, plowing through soil and leaving holes where they have been. Even the smallest leaks from containments can attract plant roots seeking water and nutrients. This can result in amplifying the severity of leaks, thereby attracting more roots, and creating further breaking up of the clay soils. The more time that elapses, the higher the likelihood of one or more of these factors impacting a clay lining system.

Geosynthetic lining systems have many safeguards that defend against attacks by Mother Nature and her various forces. For starters, many geosynthetics are formulated to withstand large temperature variations. Whether the application calls for an exposed or buried liner, freeze cracking isn’t a problem if the correct liner is selected for the project and climate. Geosynthetics also come in a wide array of flexibility, which is a benefit in areas where karst topography is prevalent. This allows for movement of the subgrade without tearing or damaging the lining system. As far as flora and fauna are concerned, reinforced geomembranes have the added advantage of high tensile and tear strengths. This makes it very difficult for rodents and roots to penetrate, keeping the liner intact for long lifespans.

Repairs

At the end of the day, after Mother Nature or other mechanical damage has been done, clay liners are not simple to repair. The first step is to completely drain the pond of its contents. Next the addition of more clay or excavating and re-applying new clay to create a thicker, continuous layer of substrate is required. This can decrease the capacity of the pond, as more clay is added to the bottom and sides. Repairs of clay liners can also come with a hefty price tag as more clay material is required as we will discuss next.

At the end of the day, after Mother Nature or other mechanical damage has been done, clay liners are not simple to repair. The first step is to completely drain the pond of its contents. Next the addition of more clay or excavating and re-applying new clay to create a thicker, continuous layer of substrate is required. This can decrease the capacity of the pond, as more clay is added to the bottom and sides. Repairs of clay liners can also come with a hefty price tag as more clay material is required as we will discuss next.

Alternatively, repairs to geosynthetic lining systems can be more straight-forward and require less work. For starters, the pond contents need only be lowered to the depth where the leak is located. After thorough cleaning, patching can make a geomembrane as watertight as when it was originally installed. Most of the time, the majority of repair costs comes from personnel, as relatively little geosynthetic materials are needed to patch the lining system.

Cost

Though clay is naturally occurring, material costs could add up quickly. Unless the soils on-site are naturally high in clay content, shipping clay to the project location will be necessary. If clay must be imported the carbon footprint for simply hauling the material will be much greater than geomembrane. At 12” thick, it would take 740 – 10-yard trucks of clay to equal 1 semi load of geomembrane with 200,000 SqFt of material on it. With the increase in trucking costs over the last few years, the materials price tag for a clay liner may be more than most bargain for. From there, the cost involved in spreading and compacting the clay compounds the costs significantly. When deploying and compacting clay, more heavy machinery, time and labor are involved vs. a geosynthetic lining system.

Depending on the project and specifications, one layer of geomembrane may be all that is required to have a leak free detention basin that will last decades. Some geomembranes can be pre-fabricated in a factory prior to arrival onsite. This can minimize, if not eliminate the need for seaming and quality control testing at the project location. Today when time is money, a fabricated geomembrane can add up to fast savings.

Environment

Environment

Clay is natural, so it is naturally good for the environment, right? That has the potential to be very wrong! Depending on the pond’s contents, cracking and leaking in clay-lined ponds can put the surrounding environment at risk. Contaminated drinking water and fish die-offs are a few of the potential results of a faulty lining system.

As we have already described, clay may not be as effective as a quality-installed geosynthetic lining system. When our environment is on the line, consider a geomembrane that has been time-tested and expertly installed to ensure contaminants stay contained.

Still unsure about whether your project is a good candidate for clay vs. a geomembrane liner? ICS will help you navigate the pros and cons of clay for your situation.

Environment

Environment