While sandbags are mostly associated with flooding, they have a wide array of uses, especially in the geomembrane world. Any time a geomembrane liner is exposed, the wind poses a threat of lifting it and uncovering the substrate. Not only does this leave the target substance uncovered and subject to the elements but can also cause irreparable damage to the geosynthetic liner. Sandbags provide essential ballast to ensure your geomembrane cover stays put. ICS fabricates long-term sandbags for use in a variety of applications.

What type of sandbag should be used for my application?

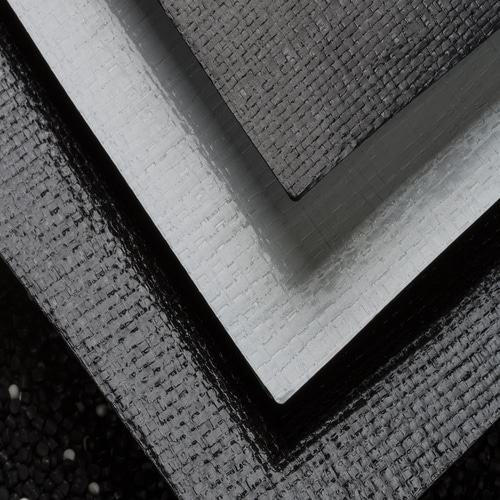

ICS’s long-term ballast sandbags are fabricated from reinforced polyethylene in 8 Mil, 12 Mil and 20 Mil thicknesses and hold 30 to 50 lbs each depending on media and volume. Determining the best choice for your project is dependent on how long they will be in use and what types of elements they will be exposed to. For projects that will be uncovered for five years and under, an 8 Mil sandbag will do the trick. Longer-term exposed applications would be recommended to use our 12 Mil product for 5-8 years, and our 20 Mil product for an extended 8+ year ballast system.

How many sandbags area needed for my project?

A variety of factors are taken into account when determining the optimal number of sandbags to provide adequate ballast on a project site. The biggest contributing factor taken into account is wind and weather patterns at the project location, with other considerations such as snow load, slope and the absence or presence of anchor trenches providing additional ballast and securing of the geomembrane. While the exact number and location of sandbags is very site-specific and may be specified by project engineers, either a 5’ X 10’ or a 10’ x 10’ grid system is the most typical.

Another factor to consider when determining the placement and quantity of sandbags for your application are any slopes in the project design. To reduce the risk of sandbags slipping down slopes, it is recommended to tether sandbags together to further stabilize the grid pattern and reduce the risk of your ballast sliding to the toe of the slopes. A high strength rope with good UV properties is required. Tethering sandbags together for a stable grid pattern can also provide further wind disruption in areas where gusts are a particular issue.

What are some specific applications?

There is a wide array of applications that utilize sandbags as ballast. Landfill construction is one of the broadest uses when it comes to the employment of long-term sandbags. New landfill construction, as well as temporary landfill covers often lead to geosynthetic lining systems being left exposed for long periods of time until they begin to be filled with refuse, or final capping takes place. Another widely used application of long-term sandbags is ballast for large tarps or stockpile covers for goods that need to be kept out of the elements for long periods. The experienced team at ICS can also fabricate custom sandbags sewn directly into stockpile covers, or other applications. Contact ICS to keep your geomembrane project from flying away!