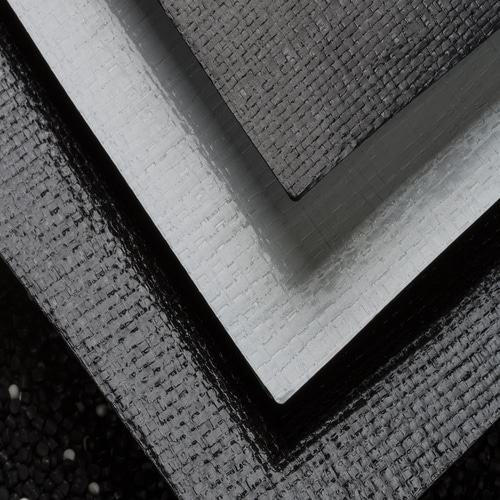

Stockpile covers are fundamentally large tarps that protect merchandise being stored out of doors until it is either processed or moved to its intended destination.Many external factors can damage stock that is stored outdoors without the proper protection. These include UV degradation, wind, precipitation and mechanical or animal tampering. Some vendors do not have the indoor capacity to store substantial quantities of goods for an extended period. In these cases, stockpile covers are a cost-effective, reusable option to keep wares on-site and out of the elements. Common applications include salt, grain, sand, fertilizer, and other raw materials.