In a world where “going green” is the cool thing to do, harnessing the power of water in the form of hydroelectricity is the largest source of clean, renewable energy in the United States today. According to hydro.org, “hydropower accounts for 52 percent of the nation’s renewable electricity generation and 7 percent of total electricity generation”, potentially leaving millions in the dark if a reliable and consistent flow of water is not realized. The various types of hydropower plants in use today each have their own unique uses for geomembranes to assist with the conservation and delivery of water within their systems, helping to provide green energy more efficiently for the masses.

Impoundment

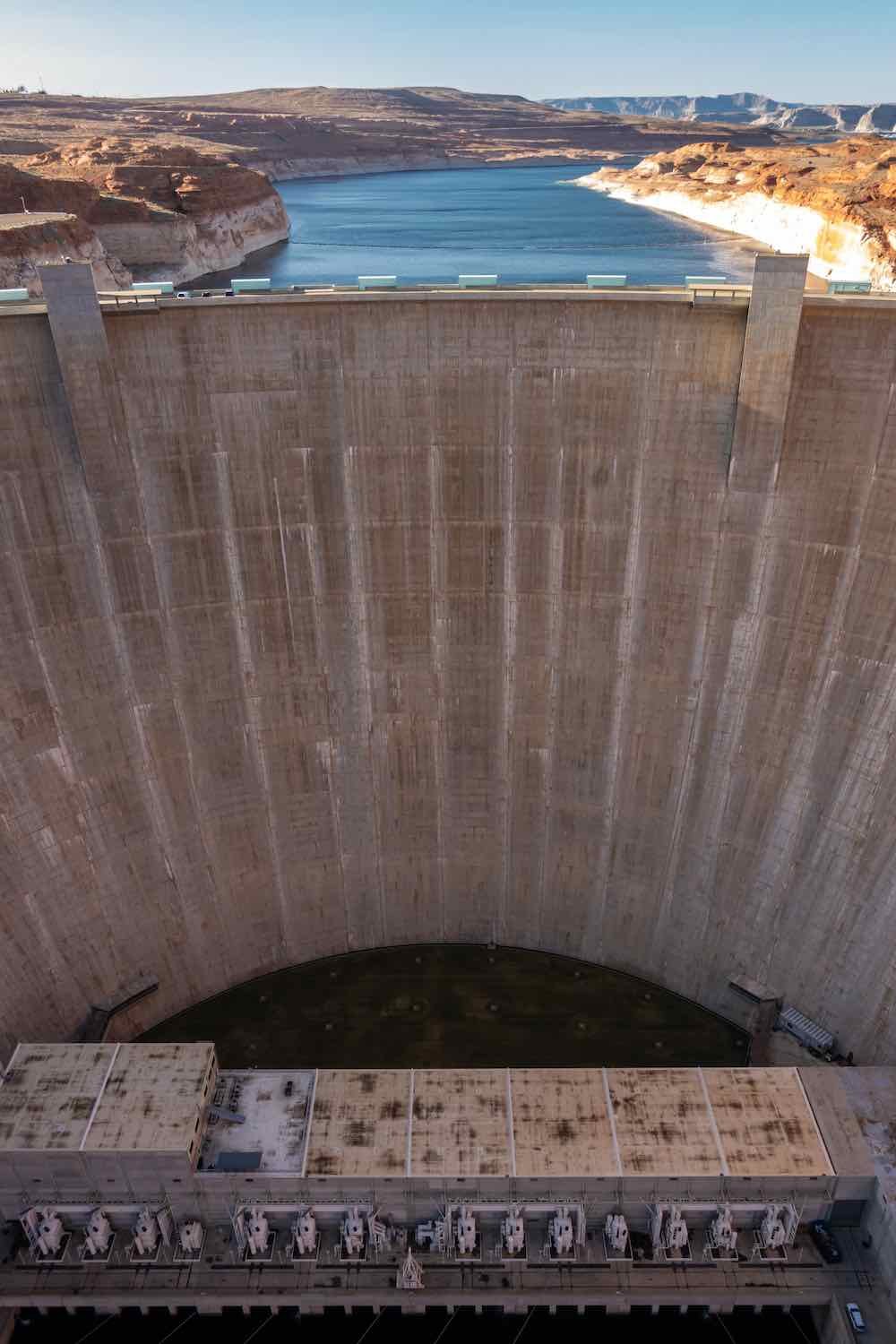

The most common form of hydropower generation comes in the form of an impoundment behind a dam. The reservoir created by the dam is the crux of this system. This harnessed water flows through turbines, connected to a generator which in turn produces electricity that is wired out to consumers. Containing as much water as possible and directing it to only flow through the turbines, or out of an overflow structure as necessary, is important to both achieving an efficient system, and increasing the longevity and safety of the dam.

Losing water through seepage into the ground from the impoundment is one area that can be improved by the installation of a geosynthetic lining system. The soil type in the location of a current or planned reservoir can make all the difference in that containment being watertight. In the absence of thick, clay soils, a geosynthetic lining system can be a cost-effective solution to water loss through seepage into the ground by providing a barrier between the contained water and porous substrates.

Seepage does not only occur within impoundments but can also be seen at the dams themselves. Not only does this pose a problem to the efficiency of the dam, but also its longevity and the safety of the area downstream of the impoundment. As water finds its way through small cracks within the dam’s structure, its erosive nature increases the size of holes and cracks, which can also be exacerbated in four-season climates where freeze-thaw cracking accelerates the issue. Installing a geomembrane lining system to the upstream face of dams is an effective means of preventing or reducing loss of water via seepage. Not only is the cost of a geoliner system comparable to other means of coating, in some cases can have a service life of 40-50+ years vs. alternatives such as gunite which has a life expectancy of 20 years. To top it off, geosynthetic lining systems have fewer environmental issues during installation when compared to coatings such as shotcrete and polysulfide, which require more environmental safeguards and can decrease seepage by 40-90% in some cases (Dams and Civil Structures: Geomembrane Installed to Control Leakage at Gem Lake Dam, by John C. Stoessel and John A. Wilkes).

Diversion

In the case of a diversion or run of the river hydroelectric plant; only a portion of the water from a river is channeled to spin the turbines and may not require a dam or impoundment at all. In this situation, it is again important to harness all of the diverted water that is directed to the powerhouse and turbines to achieve the greatest efficiency. If the ideal substrate is not present as mentioned above, a geosynthetic lining system can be used to line the canal that delivers water to generate electricity, as well as the plant’s outflow to reduce erosion and ensure delivery of the water to its intended destination. The recommended liner we recommend and supply for this type of application would have high strength and puncture resistance, such as Raven’s Dura-Skrim line of products.

Pumped Storage

A pumped storage hydroelectric system takes advantage of periods where there is low-energy usage to store up and save energy for occurrences of high-usage demands. When electricity demand is low, water is pumped from a reservoir at a lower elevation to a basin at a higher elevation where it is stored until demand passes a threshold warranting the release of the water to the turbines, thereby creating energy. As discussed above, geosynthetic lining systems can be beneficial to ensure the water within this system stays intact by lining the reservoirs and is diverted to the correct location by lining any canals needed within the system. ICS has an experienced sales, design and installation staff to help make your hydroelectric power system efficient and watertight!